The Evolution of Hastelloy Forgings: A Metallurgical Marvel

Release time:

2024-06-24 17:21

**Introduction**

Hastelloy is a high-performance alloy known for its exceptional corrosion resistance and heat resistance properties. In this article, we will delve into the evolution of Hastelloy forgings, tracing their development from their inception to their current state as a metallurgical marvel.

**The History of Hastelloy**

Hastelloy was first developed in the early 20th century by Haynes International, Inc., a leading manufacturer of high-performance alloys. The alloy was originally created to withstand the harsh conditions of chemical processing plants, where corrosion is a major concern. Over the years, Hastelloy has evolved to become one of the most widely used materials in industries such as aerospace, oil and gas, and power generation.

**Properties of Hastelloy**

One of the key properties of Hastelloy is its exceptional corrosion resistance. The alloy can withstand a wide range of corrosive environments, including acids, bases, and salts. Hastelloy is also known for its high temperature resistance, making it ideal for applications where heat is a factor. Additionally, Hastelloy has excellent mechanical properties, making it a versatile material for a variety of applications.

**Applications of Hastelloy**

Hastelloy forgings are used in a wide range of industries, including aerospace, chemical processing, and power generation. In the aerospace industry, Hastelloy is used in components such as turbine blades and heat exchangers. In the chemical processing industry, Hastelloy is used in reactors, distillation columns, and piping systems. In the power generation industry, Hastelloy is used in gas turbines, boilers, and heat exchangers.

**The Future of Hastelloy**

As technology continues to advance, the demand for high-performance materials like Hastelloy is expected to grow. Researchers are constantly developing new alloys and processes to improve the properties of Hastelloy and expand its potential applications. With its unique combination of properties, Hastelloy is poised to remain a key player in the metallurgical industry for years to come.

**FAQs**

1. What is Hastelloy?

Hastelloy is a high-performance alloy known for its exceptional corrosion resistance and heat resistance properties.

2. What are the applications of Hastelloy?

Hastelloy is used in industries such as aerospace, chemical processing, and power generation for components like turbine blades, reactors, and heat exchangers.

3. Who developed Hastelloy?

Hastelloy was first developed by Haynes International, Inc. in the early 20th century.

4. What are the key properties of Hastelloy?

Hastelloy has exceptional corrosion resistance, high temperature resistance, and excellent mechanical properties.

5. What does the future hold for Hastelloy?

As technology advances, the demand for Hastelloy is expected to grow, with researchers continually developing new alloys and processes to improve its properties.

**Conclusion**

In conclusion, the evolution of Hastelloy forgings has been a remarkable journey, showcasing the ingenuity and innovation of the metallurgical industry. With its exceptional properties and diverse applications, Hastelloy continues to be a metallurgical marvel that will shape the future of high-performance alloys for years to come.

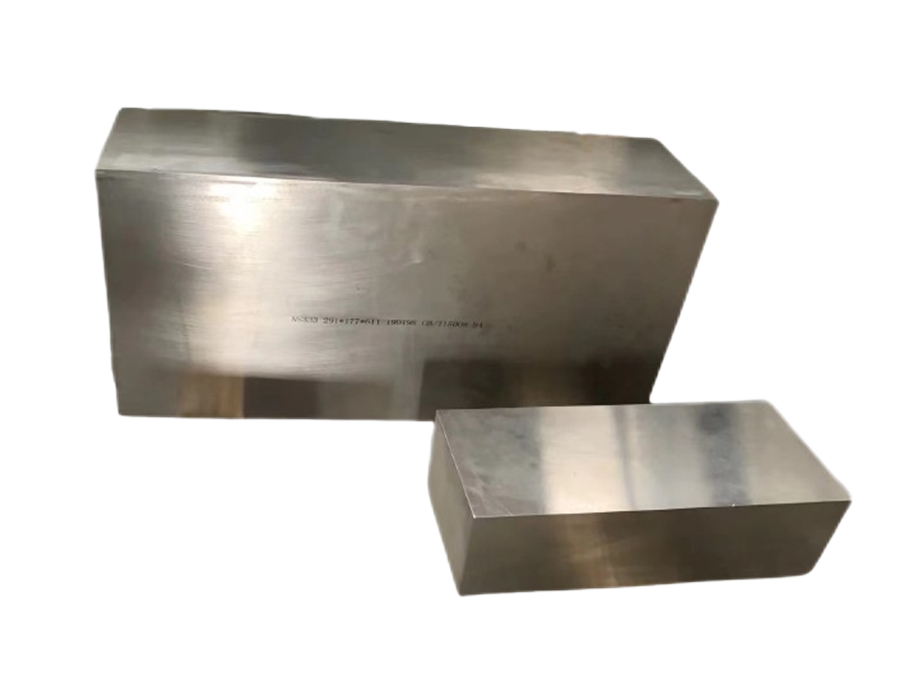

Hastelloy forgings

Related News

The Art and Precision of Forging: Unlocking the Benefits of Precision Forging

2025-06-20

Precision forging is a sophisticated manufacturing process that significantly enhances the mechanical properties and dimensional accuracy of metal components. This technique involves shaping metal into desired forms through the application of high pressure, often at elevated temperatures. Unlike traditional forging methods, precision forging utilizes advanced technology and precise control mechani

Understanding Precision Forging: Key Insights for Professionals in Metalworking

2025-06-18

Precision forging is a sophisticated manufacturing process that involves shaping metal components through the application of controlled pressure and heat. This technique is distinguished by its ability to create parts with exceptional accuracy, consistency, and strength, making it a preferred choice in industries where precision is paramount. One of the primary advantages of precision forging is i

How Monel K500 Forging Enhances Corrosion Resistance in Metal Parts

2025-06-17

Introduction to Monel K500: The Corrosion-Resistant Metal Monel K500 is a nickel-copper alloy renowned for its exceptional corrosion resistance, strength, and versatility. It stands out in various industries, including marine, chemical processing, and aerospace, where metal components must endure harsh environments. This article delves into how the forging process of Monel K500 enhances its corr