Inconel 718

For any temperature and concentration of hydrochloric acid has excellent corrosion resistance. At the same time, it has good corrosion resistance to sulfuric acid, acetic acid, formic acid, phosphoric acid and other non-oxidizing media.

Classification:

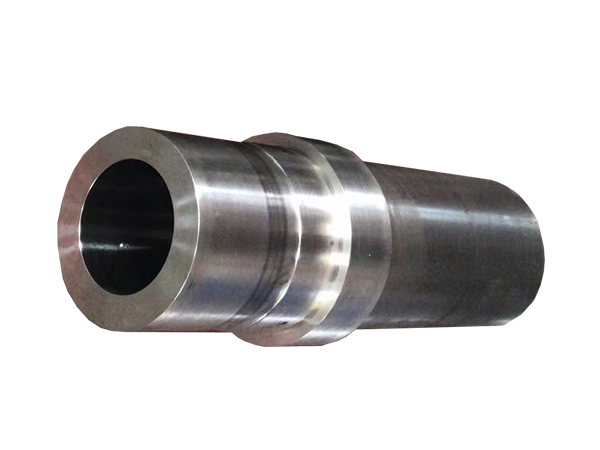

Product Display

Key words: nickel-based alloy material

- DESCRIPTION

-

Overview

Inconel718 alloy is a nickel-based high-temperature alloy strengthened by body-centered tetragonal y" and face-centered cubic γ phase precipitation. It has good comprehensive performance in the temperature range of -253 ~ 700°C. The yield strength below 650°C ranks first among deformed high-temperature alloys and has good fatigue resistance. It has radiation resistance, oxidation resistance, corrosion resistance, good processing performance, welding performance and long-term organizational stability. It can manufacture various complex parts and has been widely used in aerospace, nuclear energy and petroleum industries within the above temperature range.

Chemical composition

Carbon C: ≤0.08, chromium Cr: 17.0~21.0, nickel Ni: 50~55, cobalt Co: ≤1.00, molybdenum Mo: ≤2.8~3.30, aluminum Al: 0.20~0.8, titanium Ti: 0.65~1.15, iron Fe: excess, niobium Nb: 4.75~5.50, boron B: ≤0.006, manganese Mn: ≤0.35, silicon Si: ≤0.35, sulfur S: ≤0.015, copper Cu: ≤0.30, phosphorus P: ≤0.015, Mg: ≤0.01. Metallographic structure

Inconel718 alloy is a nickel-based high-temperature alloy strengthened by body-centered tetragonal y" and face-centered cubic γ phase precipitation

Characteristics

At -253 It has good comprehensive performance in the temperature range of ~ 700°C. The yield strength below 650°C ranks first among deformed high-temperature alloys and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, as well as good processing performance, welding performance and long-term structural stability.

Corrosion resistance

It has high strength and good toughness below 650℃ and is resistant to oxidation and corrosion in high and low temperature environments.

Application

Due to its high temperature strength, excellent corrosion resistance and easy processing at 700C, it can be widely used in various high-demand occasions.

(1) Steam turbine

(2) Liquid fuel rocket

(3) Cryogenic engineering

(4) Acidic environment

(5) Nuclear engineering

A nickel-chromium-molybdenum alloy with the addition of niobium, which acts with molybdenum to harden the alloy matrix, thereby exhibiting high strength properties without heat treatment. The alloy is resistant to various harsh corrosive environments, especially pitting and crevice corrosion. It is used in chemical, aviation and marine engineering, pollution control equipment, and nuclear reactors.

The low carbon alloy 625 after softening annealing is widely used in the chemical process industry, and its good corrosion resistance and high strength make it can be used as a thin structural component. 625 alloys can be applied in contact with seawater and subjected to high mechanical stress. Typical application areas:

1. Components of organic chemical processes containing chlorides, especially where acid chloride catalysts are used;

2. For the manufacture of digesters and bleaching ponds for the pulp and paper industry;

3. The absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, deflector and flue in the flue gas desulfurization system;

4. For the manufacture of equipment and components used in acid gas environments;

5. Acetic acid and acetic anhydride reaction generator;

6. Sulfuric acid condenser.

Related Products

Online Message