Hastelloy C-276

For any temperature and concentration of hydrochloric acid has excellent corrosion resistance. At the same time, it has good corrosion resistance to sulfuric acid, acetic acid, formic acid, phosphoric acid and other non-oxidizing media.

Classification:

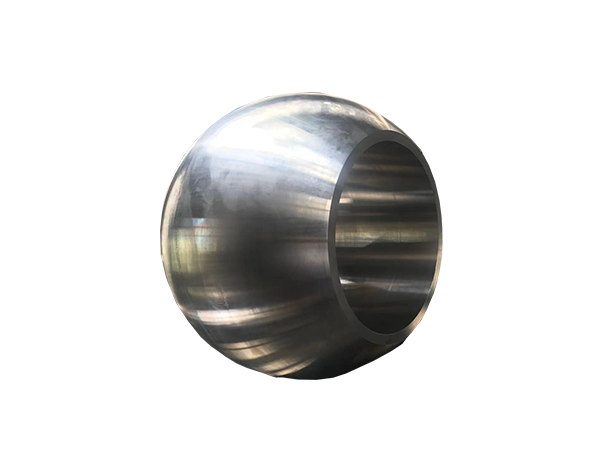

Product Display

Key words: nickel-based alloy material

- DESCRIPTION

-

Overview

Hastelloy C-276 is a tungsten-containing nickel-chromium-molybdenum alloy with extremely low silicon and carbon content. It has been widely used in the chemical and petrochemical fields, such as in components and catalytic systems that come into contact with chloride-containing organic matter. This material is especially suitable for use in high temperature, inorganic and organic acids mixed with impurities (such as formic acid and acetic acid), and seawater corrosion environments.

chemical composition

Carbon (C) ≤ 0.01, Manganese (Mn) ≤ 1.00, Nickel (Ni) ≥ 57, Silicon (Si) ≤ 0.08 Phosphorus (P) ≤ 0.04, Sulfur (S) ≤ 0.03, Chromium (Cr) 14.5~16.5, Iron (Fe)4.0~7.0, molybdenum (Mo)15.0~17.0, tungsten (W)3.0~4.5, cobalt (Co) ≤2.5

Metallographic structure

C-276 has a face-centered cubic lattice structure

characteristic

① In both oxidizing and reducing atmospheres, it has excellent corrosion resistance to most corrosive media.

②Excellent resistance to pitting corrosion, crevice corrosion and stress corrosion. The higher Mo and Cr content make the alloy resistant to chloride ion corrosion, and the W element further improves the corrosion resistance. At the same time, Hastelloy C-276 alloy is one of the only materials resistant to corrosion by moist chlorine, hypochlorite and chlorine dioxide solutions, and is resistant to high-concentration chloride solutions such as ferric chloride and copper chloride. Remarkable corrosion resistance. It is suitable for sulfuric acid solutions of various concentrations and is one of the few materials that can be used in hot concentrated sulfuric acid solutions.Corrosion resistance

The higher molybdenum and chromium content makes Hastelloy C-276 alloy resistant to corrosion by various chemical media, including reducing media, such as phosphoric acid, hydrochloric acid, sulfuric acid, chlorine gas, and organic or inorganic chlorine-containing media. Due to its high nickel content, Hastelloy C-276 is highly resistant to stress corrosion cracking caused by chlorine, even hot chloride solutions.

application

It has been widely used in the chemical and petrochemical fields, such as in components and catalytic systems that come into contact with chloride-containing organic matter. This material is especially suitable for use in high temperature, inorganic and organic acids mixed with impurities (such as formic acid and acetic acid), and seawater corrosion environments. Other areas of application: Pulp and paper industry, such as digestion and bleaching vessels; scrubbers, reheaters, wet steam fans, etc. in FGD systems; equipment and components operating in acidic gas environments; reactors for acetic acid and acidic products ; Sulfuric acid condensers; Methylene diphenyl isocyanate (MDI); Production and processing of impure phosphoric acid

A nickel-chromium-molybdenum alloy with the addition of niobium, which acts with molybdenum to harden the alloy matrix, thereby exhibiting high strength properties without heat treatment. The alloy is resistant to various harsh corrosive environments, especially pitting and crevice corrosion. It is used in chemical, aviation and marine engineering, pollution control equipment, and nuclear reactors.

The low carbon alloy 625 after softening annealing is widely used in the chemical process industry, and its good corrosion resistance and high strength make it can be used as a thin structural component. 625 alloys can be applied in contact with seawater and subjected to high mechanical stress. Typical application areas:

1. Components of organic chemical processes containing chlorides, especially where acid chloride catalysts are used;

2. For the manufacture of digesters and bleaching ponds for the pulp and paper industry;

3. The absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, deflector and flue in the flue gas desulfurization system;

4. For the manufacture of equipment and components used in acid gas environments;

5. Acetic acid and acetic anhydride reaction generator;

6. Sulfuric acid condenser.

Related Products

Online Message